Demant eliminates 51 tonnes of plastic from production

While keeping circularity, quality and functionality in mind, Demant’s Hearing Aids business has successfully optimised the production of selected hearing aid accessories. The project reduces plastic consumption significantly, improves waste management and it is a testament to Demant’s effort to bring forward more sustainable practices in production.

Based on 2024 production volumes, the completion of the entire project is estimated to reduce plastic consumption by 51 tonnes a year. This exceeds the initial expectations for the project. In addition, the project has inspired other developers in Demant to implement similar solutions in other components when possible.

Big impact project

In 2020, an investigation into the plastic consumption revealed that the containers for filters alone make up a significant part of the yearly plastic used for producing hearing aids. More precisely, Demant sells more than 10.3 million of these accessories every year, and reducing the plastic used for each therefore entails a large impact on the overall plastic consumption.

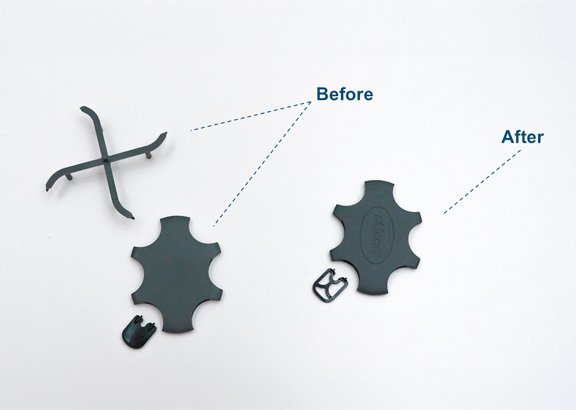

First, a redesign introduced a material with lower density and a moulding tool that generates less waste. This effort alone eliminates 11.5 tonnes of plastic annually. Second, new flattened and hollowed out handles are made from 100% granulated plastic scrap from other parts of the production.

Combined, the initiatives result in a 53% reduction in plastic consumption each year, all while maintaining the same functionality for the hearing aid user.

Back to latest news